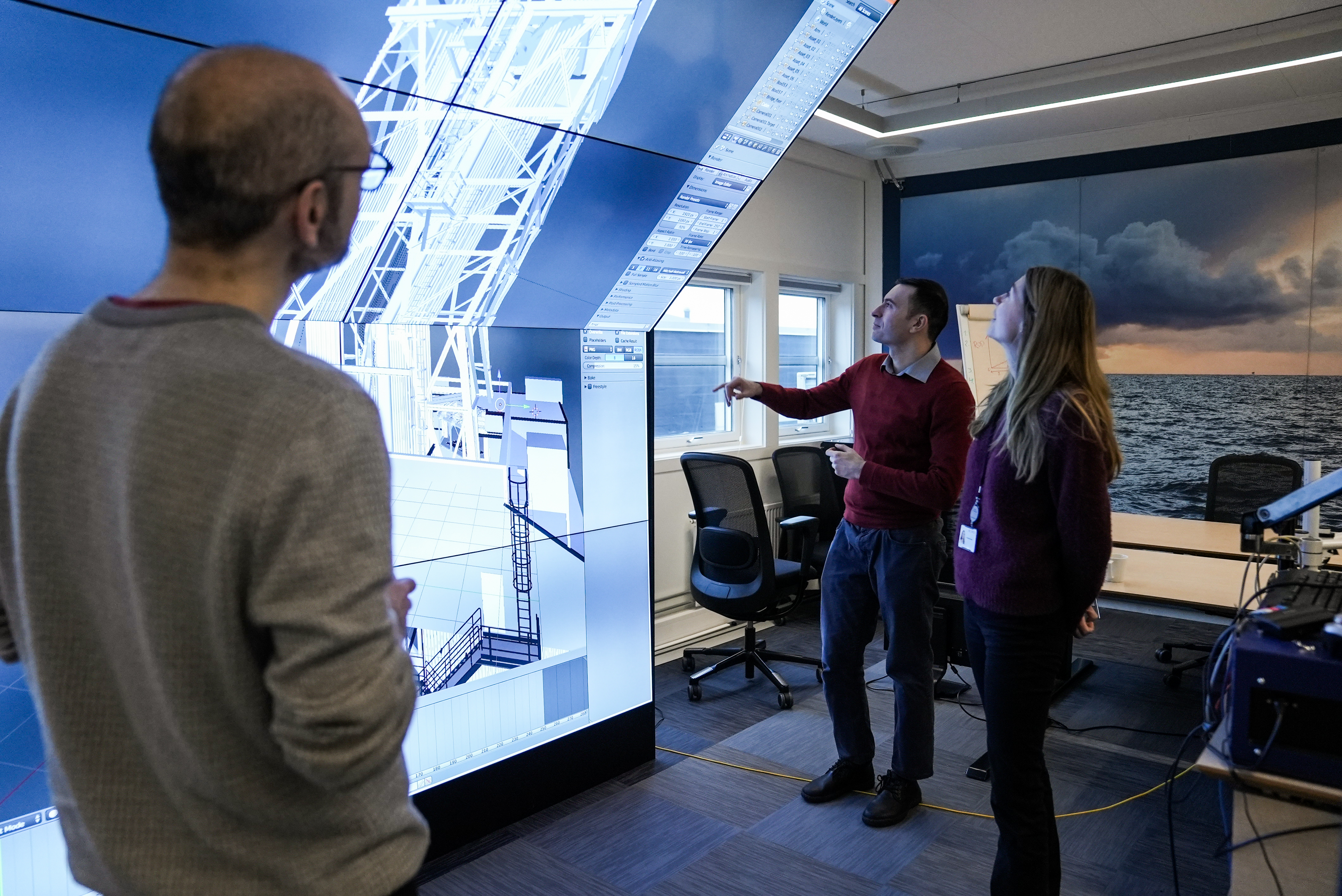

OpenLab Drilling is an advanced simulator for research and technology development within drilling automation and digitalisation. The simulator is unique in providing realistic data for research and innovation projects. OpenLab has been a key contributor for the digital transition of drilling operations, and an enabler of developing and demonstrating the world’s first autonomous drilling system in 2021 at NORCE. It is also being used outside these domains in AI and control systems research.

More than 1000 users have visited or used OpenLab so far in 2023.

– OpenLab has proven to accelerate the readiness of new drilling technologies. Research and innovation speed will be a key factor in reaching our net-zero goals. We want to expand OpenLab to address CO2 storage and leakage, and problems related to underground hydrogen storage, says Jan Einar Gravdal, Project Manager at OpenLab and Chief Scientist in NORCE Energy Modelling and Automation.

When storing CO2 in a reservoir the risk for leakage in and around the well must be minimised, and any leakage needs to be mitigated.

– With the expansions of OpenLab we can contribute to developing and testing systems that can detect and handle these problems and help prevent them, says Jan Einar Gravdal.

New possibilities within hydrogen storage

On the Norwegian continental shelf and in Europe there is enormous potential for storage of hydrogen in old oil and gas fields and in salt caverns. However, one of the main challenges with storing hydrogen underground is the risk of leakage from the wellbore and the potential risk of blowouts through or around the well.

– The petroleum industry has worked on leakage detection systems and mitigation measures for decades, and hydrogen underground storage is associated with similar risks of leakage and potentially also blowouts. We now want to include new simulation capabilities into OpenLab providing hydrogen leakage and blow out simulations. There is an urgent need for research and improved technology to handle risks of leakage and blowouts if hydrogen underground storage is going to be a viable solution, Jan Einar.